performance and characteristics

This type of seat is composed of a wooden backrest, a seat plate (including fabric, seat steel skeleton, polyurethane foam) connected with a turning mechanism.

performance and characteristics

►►The back plate and seat plate are made of wooden multilayer board and high-frequency pressing. The skin is beech skin and coated with high-frequency polyester polishing paint. The shape is beautiful and elegant. Due to the high-frequency pressing, it will not crack for a long time and has good moisture-proof function.

►►The back core is made of high-quality and high-rebound polyurethane foam material, which is molded at one time by thermal curing process. Its shape is designed according to the principle of human body function, and the seat feels comfortable and does not fatigue for a long time. The backing plate is molded from a multilayer plate.

The soft core of the seat is made of high-quality high-resilience polyurethane foam material and steel structure frame (the frame is built with "S" type spring), which is molded at one time by thermal curing process.

►►The armrest is made of cast aluminum and is polished and sprayed. Cast aluminum skeleton sealing plate is made of 0.5cm sponge attached cloth for external use of special density board. The upper armrest is made of solid wood and beech. The armrest is coated with polyester sanding paint or self-skinning soft armrest to make the seat beautiful and durable. The upper armrest is provided with a rotary writing board, and the overall structure fully meets the load-bearing requirements during writing.

►►The fabric is manually sewn and glued to the foam, with a smooth appearance and no wrinkles.

The color and variety of the fabric are selected by the user and can be treated with flame retardant. Its flame retardant performance is tested according to GB/T5455-1997 "Vertical Method for Textile Combustion Performance Test". All performance indexes can meet the B1 level requirements of the combustion performance judgment conditions for decorative fabrics in "Code for Fire Protection Design of GB50222-95 Building Interior Decoration", and its combustion performance is B1 level standard.

►►The seat steel structure frame is made of high-quality material steel and steel plate, and the stamping parts are welded with carbon dioxide protection, and are equipped with "S" springs to increase the elastic comfort of the seat.

►►The seat shaft is made of hexagonal steel, the shaft bracket is made of nylon 66 injection molded parts, and the shaft sleeve is made of high-quality engineering polypropylene.

►►The seat is turned over by its own weight, and the counterweight is determined after fine measurement and test. The seat is turned over flexibly, without noise and maintenance.

►►All fasteners (bolts, nuts, pad height) are galvanized or black-boiled on the surface of national standard parts, with strong anti-corrosion ability.

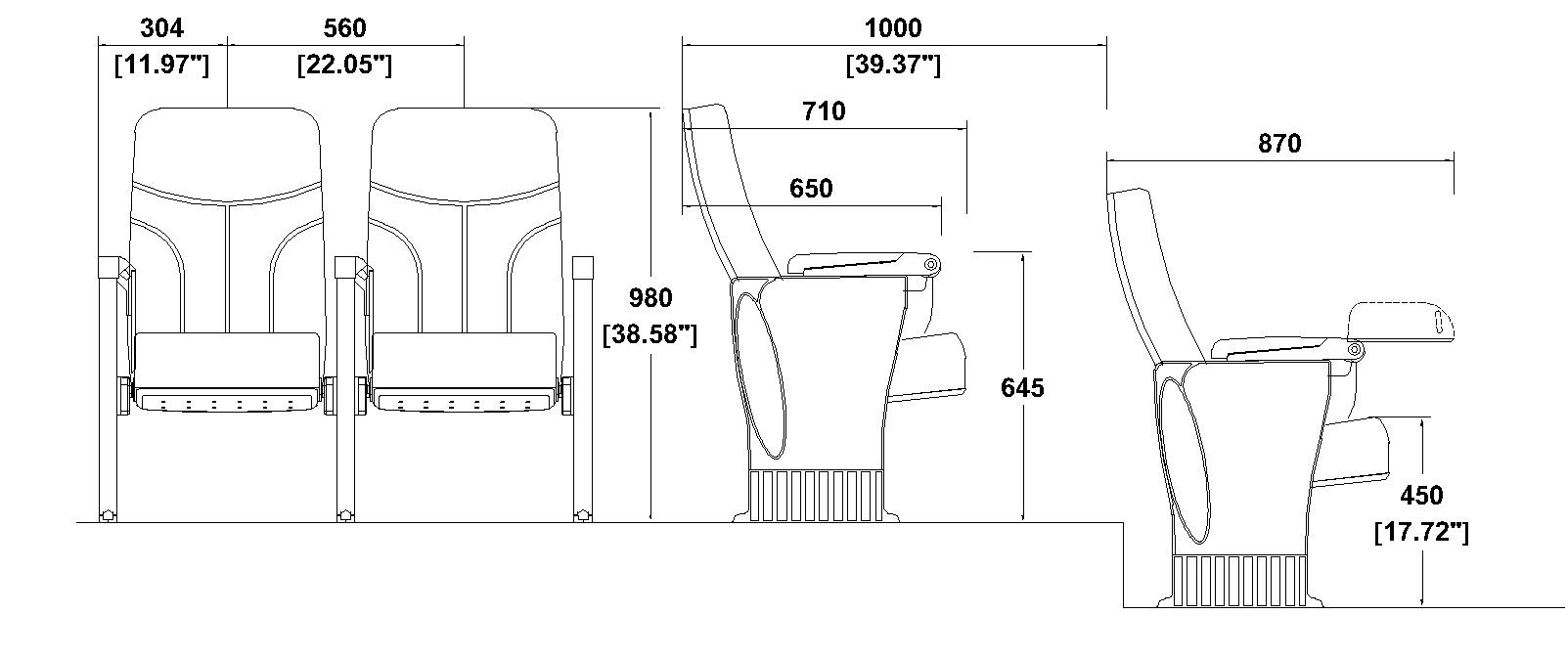

Technical parameters

|

Chair height |

98cm |

Center distance of row chair |

56cm |

|

seat height |

45cm |

Row distance requirements |

≥ 95cm |

|

Armrest height |

64.5cm |

Seat load-bearing |

≥ 1470N |

|

Minimum Length |

65cm |

foam density |

≥ 40kg/m3 |

|

Maximum length |

87cm |

Number of seat flips |

≥ 100000 times |

|

Seat depth |

46cm |

Net width |

50cm |

wireframe diagram

DDL-1

Contact Us

Key words:

Classification