Structure composition

The seat is mainly composed of iron armrest, wooden armrest, backrest, seat cushion and connecting turning mechanism.

performance and characteristics

►►The backrest and cushion are formed by a trinity mold with a built-in steel skeleton. The skeleton and fabric are placed together in the mold and become one when foamed by polyurethane. The foam density is 45kg/m3, which is soft and comfortable, does not deform, and is not easy to open glue. The back shell and seat shell are made of modified PP engineering polypropylene molding, with corrosion resistance, aging resistance, easy to clean and so on.

►►The seat number can be installed outside the seat cushion. The seat number is available in fluorescent seat number and aluminum seat number.

►►The seat back is a fixed backrest, and the fixed backrest connection structure is 3mm thick angle iron and 25*25mm rectangular tube welded and formed, which is durable and not deformed.

►►The overturning mode of the seat cushion adopts torsion spring rebound, with low noise and accurate return.

►►The seat armrest is welded with 2mm thick rectangular iron pipe, the lower anchor is stamped and formed by 2mm thick steel plate mold, and the anchor fixing hole distance is 242mm; The armrest is equipped with side plates, the side plates are covered with cloth, the upper armrest is beech wood armrest, the surface is painted and polished for many times, which has the characteristics of high strength, beautiful appearance and generous appearance.

►►All metal surfaces of the seat are subject to sandblasting and rust removal, followed by electrostatic powder spray coating for rust prevention.

►►The seat automatic rebound shaft adopts 45# high-quality steel rotating shaft, and the shaft frame and shaft sleeve are high-strength nylon injection molded parts.

►►Seat fabric a variety of colors, varieties for customers to choose and do flame retardant treatment, its combustion performance can reach B1 level flame retardant standard.

►►All connecting fasteners (bolts, nuts, self-tapping nails, rivets, etc.) are made of national standard parts, and the surface is galvanized or blackened for rust prevention.

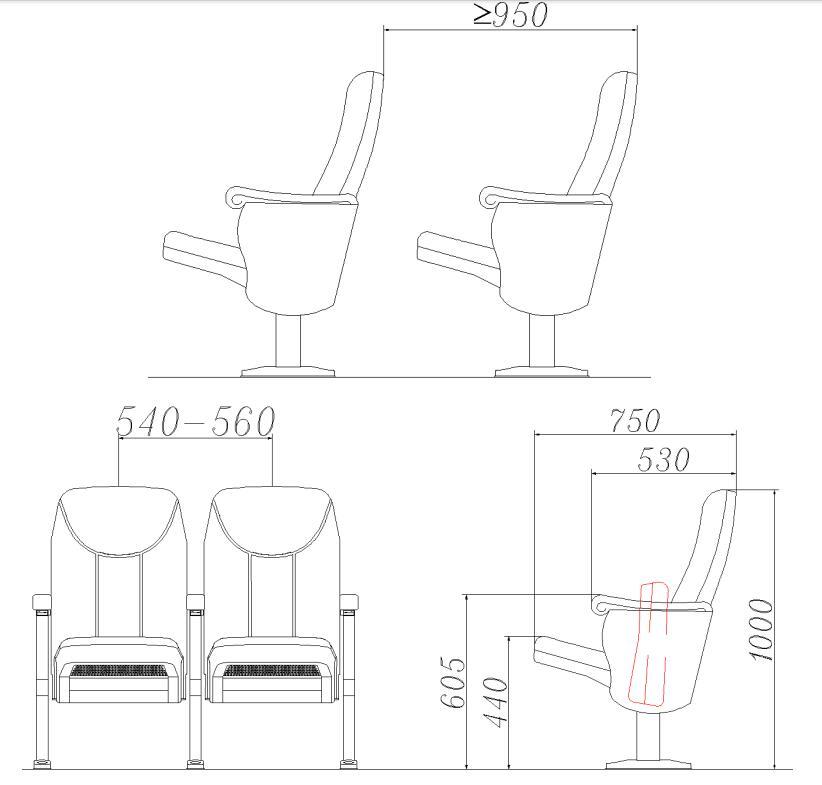

Technical parameters

|

Chair height |

100cm |

Center distance of row chair |

54-56cm |

|

seat height |

44cm |

Recommended minimum row distance |

95cm |

|

Armrest height |

60.5cm |

Minimum Length |

53cm |

|

Maximum length |

75cm |

foam density |

45kg/m3 |

|

Seat depth |

47cm |

Maximum Seat Load |

150kg |

|

back width |

49cm |

Number of seat flips |

200000 times |

wireframe diagram

Note: The unit of the appearance size shown in the figure is mm, and the individual data of the actual product may have an error of about ± 10mm.

98B3

Contact Us

Key words:

Classification